November 22, 2023

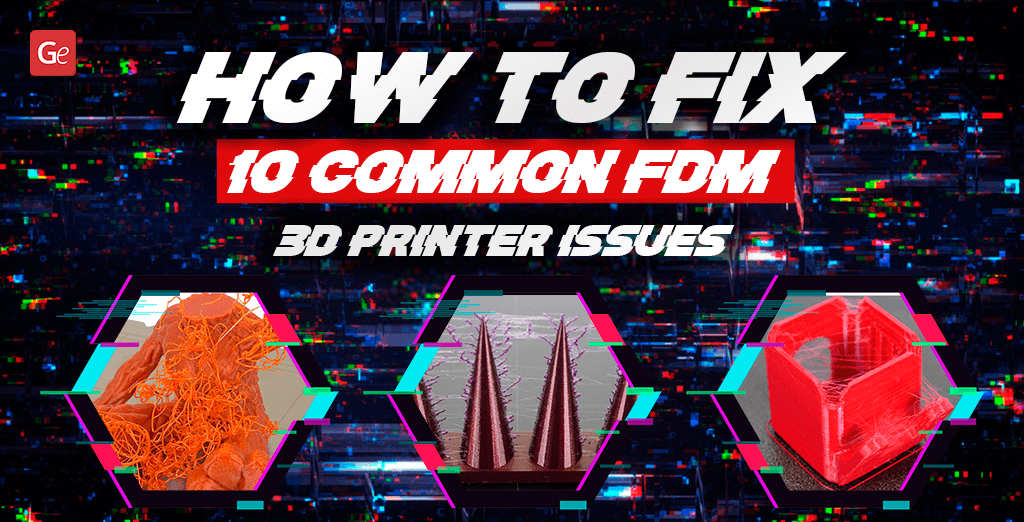

7 Most Usual Troubles With A 3d Printer How To Deal With

Troubleshooting Guide Keep in mind, nevertheless, that it's impossible to prevent leaving any type of traces after the elimination, since supports are an essential component of the model. The issue of assistance frameworks can be come close to in different ways at the modeling phase, but it undeniably is among the core parts of proper 3D-modelling. However, it's highly feasible that you'll have the ability to tweak your design's design to bypass the requirement for support frameworks. For instance, you can change the model's upright angles or include some style integral supports. We are experienced with taking care of print failings, so we really hope that this thorough troubleshooting guide can assist you to determine and address usual concerns.Construction 3D Printing Startup ICON Lays Off 20% of Staff - 3DPrint.com

Construction 3D Printing Startup ICON Lays Off 20% of Staff.

Posted: Tue, 24 Jan 2023 08:00:00 GMT [source]

Summary Of Solutions: Extrusion Quit During Printing

Perhaps one of the viewers could provide all of us a hint in the remarks? Nevertheless, it's not really necessary to comprehend the origins of the trouble in order to resolve the issue. An additional preferred cause for the issue is poor-quality filament. Although it thaws fine, a full strengthening may take fairly a long time instead of high-grade filaments. One of the most constant root cause of improper bridging is that the gap is as well long. This range depends upon the product and also tool you use. Changing the velocity in the Marlin Configuration.h documents on lines 390, 391, 393 and also 394 must deal with the concern if it is truly an acceleration issue. The apparent service for this 3D printer problem is to enhance infill thickness. The greater the fill percentage, the more powerful the infill and also the overall print. While you want every print to be solid, you don't want every print to have a great deal of infill.- If you work with tall versions, then it's most likely that the supports will certainly be exceedingly long, which boosts the possibilities of it stopping working.

- This photo nonetheless does not show any kind of indications of warping or curling.

- The print will start to raise and also appear to peel away from the bed.

Printer Troubleshooting Overview

It might likewise collect material deposit, triggering the nozzle passage to become clogged with debris. To avoid this issue, you ought to unblock the nozzle on a regular basis. If you've obtained a 3D printing problem, difficulty or question, our team is below to help.18 Lasers Power SpaceX Alums’ New Metal 3D Printing Tech - 3DPrint.com

18 Lasers Power SpaceX Alums’ New Metal 3D Printing Tech.

Posted: Wed, 01 Feb 2023 08:00:00 GMT [source]

What are the typical 3D printing troubleshooting troubles?

- Not Extruding at Start of Print. Printer does not squeeze out plastic at the beginning of the print.Not Staying with the Bed.Under-Extrusion. Over-Extrusion.

- Spaces in Leading Layers.Stringing or Oozing.Overheating.Layer Shifting. Dimension.

- One feature to take into consideration when

- developing your product is it's scale.The resolution.

- Throughout additive manufacturing, the resolution refers to the density of each layer of material being'applied.Wall thickness.The orientation.The choice of

- material.Design equilibrium. When a PLA filament absorbs dampness, it inflates, increasing the danger of extruder jams. Moisture also creates PLA to create prints with bubbles as well as voids on the surface, consequently wrecking your prints

- .

Social Links