November 7, 2023

Current Advancements In 3d Printing Of Biomaterials Journal Of Organic Design Complete Message

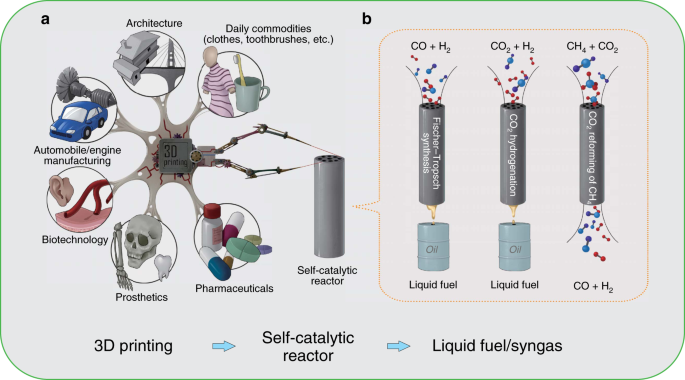

3d Printing Fads: Six Significant Developments Each layer can be seen as a thinly sliced horizontal cross-section of the eventual item. FDM has actually frequently used biocompatible polymers with low melting temperature levels. Artificial insemination research studies have actually been executed with porcine chondrocytes, computer mouse pre-osteoblasts, and also bone marrow-derived mesenchymal stem cell.- Like other 3D printers they consist of a print nozzle, tubes for feeding in the print product, a control system as well as the mechanical elements for relocating the nozzle-- yet in these printers every little thing is a little smaller sized than usual.

- The most crucial product option requirements for FDM materials are heat transfer qualities and also rheology.

- Influences can be seen in different designs utilized by Winsun, including articles on the Winsun's original news release as well as workplace of the future.

- Additive production dangers vary widely relying on the technology and materials made use of.

3 Dimensional Printing

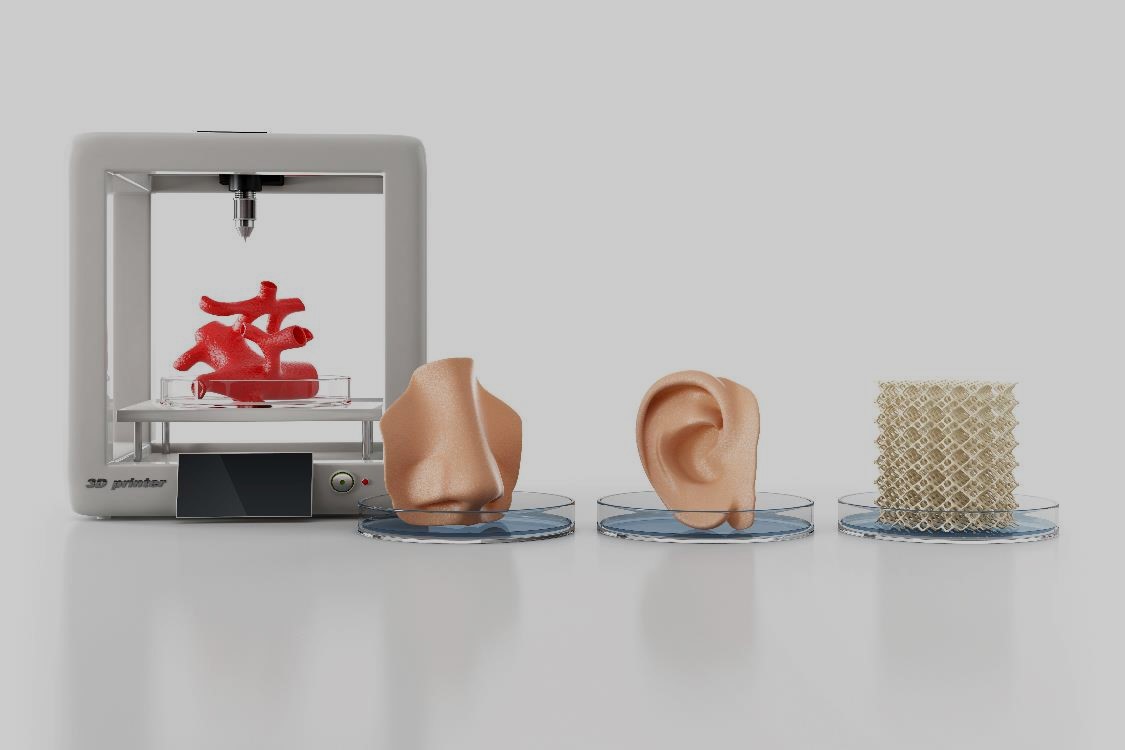

Ahn et al. bioprinted high thickness cell-laden hydrogels by squeezing out a 4 ° C cell-alginate remedy onto a -10 ° C phase to produce a structure. The alginate was crosslinked to supply strength by breeding the framework in a CaCl2 service. Good cell practicality of was shown for human mesenchymal stem cells and also human osteoblast-like cells after processing.What is the toughest 3D printing method?

Polycarbonate. According to multiple manufacturers and also customers, polycarbonate (COMPUTER) is considered the toughest consumer filament available. PC can yield incredibly high-strength components when published properly with an all-metal hot end and also a room.

What Are The Benefits Of 3d Printing?

Voxeljet commercial 3D printing and making business is an international trendsetter and technology vehicle driver for sophisticated 3D printing systems and services in production settings. We have one-of-a-kind advantages across the entire procedure chain as a result of our processes being highly efficient as well as efficient in ranges that are unmatched globally. As specified, Additive manufacturing is the umbrella term that describes all techniques of 3D printing. Any type of 3D printing strategy utilizes a CAD layout from a computer and also builds up the accurate geometric form in layers. In contrast to this technology, conventional methods typically need you to eliminate the surplus products to develop the forms you need.Unspun Unveils New 3D Weaving Machine For The Sustainable Microfactory Of The Future - CleanTechnica

Unspun Unveils New 3D Weaving Machine For The Sustainable Microfactory Of The Future.

Posted: Fri, 09 Jun 2023 02:09:55 GMT [source]

Social Links