November 22, 2023

Six Good 3d Printing Troubleshooting Guides" Fabbaloo

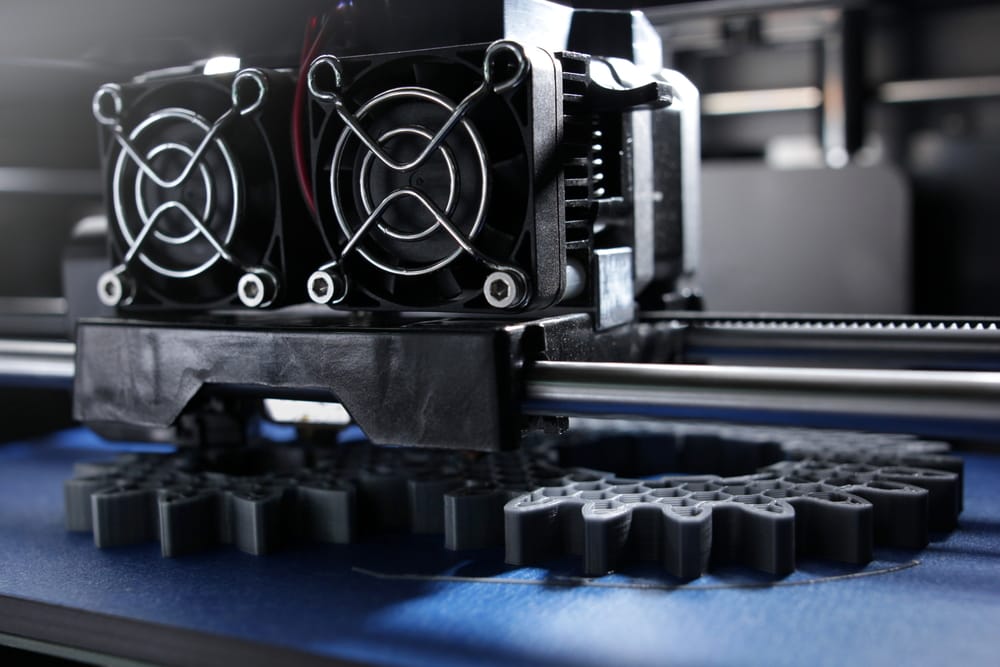

Anycubic Photon Resin 3d Printer: Ideas, Techniques, And Repairing Overview You could be lucky-- it may only be the top layers that have actually stagnated. A typical issue with Bowden design extruders is when the tubes isn't pressed right right into the HotEnd. Or completion of television is frayed or has actually been reduced at an angle. Any void there will lead to clogs eventually as the melted filament leakages out around television triggering it to flaw. Raise the Vref of the extruder stepper, offering it a little more power to perhaps push a little bit stronger without avoiding. But do keep an eye on the motor as well as vehicle driver temperatures if you do.Construction 3D Printing Startup ICON Lays Off 20% of Staff - 3DPrint.com

Construction 3D Printing Startup ICON Lays Off 20% of Staff.

Posted: Tue, 24 Jan 2023 08:00:00 GMT [source]

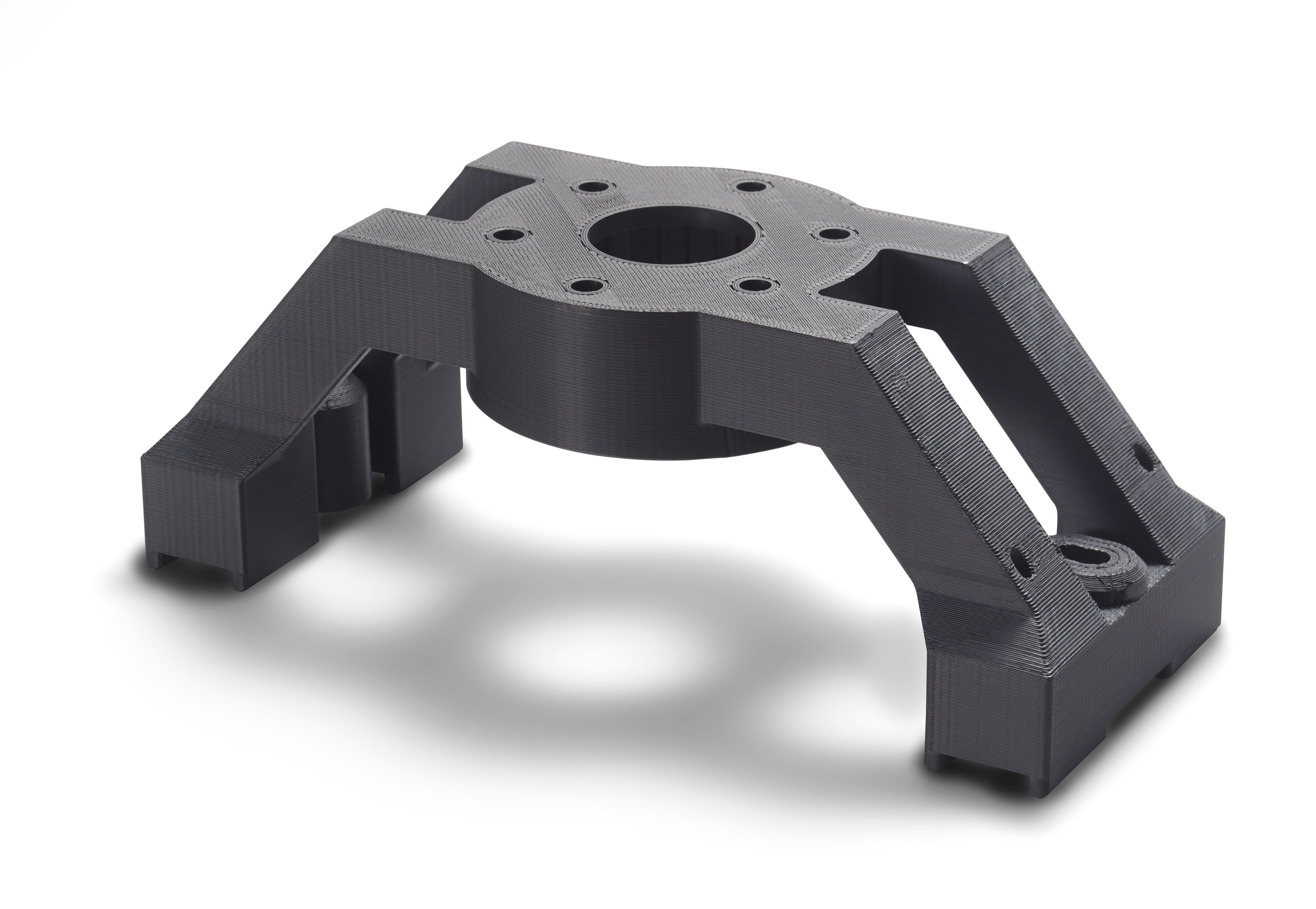

Exactly How To Fix Unpleasant Infill

Possibly among the viewers could offer all of us a tip in the remarks? Nonetheless, it's not really required to recognize the roots of the trouble in order to solve the issue. An additional preferred cause for the problem is poor-quality filament. Although it melts great, a complete strengthening might take quite time in contrast to high-grade filaments. The most regular root cause of incorrect linking is that the void is too long. This range depends on the material and device you utilize. This function has a pre-defined set of criteria that can be altered in order to control the printing process a lot more. For instance, you may wish to personalize minimal traveling because it will probably manage the stringing if laid-back activation of retraction really did not aid. The extruder nozzle might be obstructed because of numerous factors. Check for any remains of excess filament or dust inside the nozzle, considering that it might limit the printed product access. After that publish a calibration cube and also validate that the filament is squeezing out properly as well as the issue is eliminated.- Non-manifold geometry can be nicely taken care of in specialist 3D-creation collections like Blender or food processor or Meshmixer.

- Open your slicer program as well as take a look at the cooling settings.

- It may miss or tear as well as have open holes without any infill present.

- However the smaller the nozzle the lower the tolerance, so make sure to calibrate your printer appropriately.

Printer Troubleshooting Overview

Make certain to nicely clean the plate after fining sand, considering that if several of the remnants meet the resin you'll be experiencing printing troubles. After effectively manufacturing a couple of prints, you may typically find a few bits of resin swimming on the surface inside your barrel. These fragments are exceptionally important to get rid of because they may create a laser breakdown-- it will not longer be able to heal fresh resin properly. It can end up being much more unluckier - the odds that you remained in a middle of publishing a complex model before the device instantly came to a stop are extremely high. After the design is successfully separated, clean the platform if required as well as try to find any type of fractures or pits on the glass. If there are, you should transform the glass over and make use of the properly polished side. Define your printer, mainboard, stepper vehicle drivers, firmware, adjustments, slicer, and so on. Tuning the present supplied to the stepper electric motors varies significantly depending upon these variables. Printing slower enables the heat developing in the printed object to dissipate before the following pass of the nozzle over the very same location of the print. Do the basic extrusion calibration of extruder steps/mm and also extrusion multiplier. Support frameworks are usually not published strong, but rather, like infill, use a percent, frequently called assistance thickness. Enhance this density to boost the surface area top quality of the component printed above the support.First Layer Issues

Component cooling fans should not get to more than 10-20% with ASA. A warm ambient temperature is best yet that doesn't mean print at the most popular temperature level within the range. Attempt decreasing your printing temperature if you experience over heating with ASA. 3D printer stringing as well as nozzle oozing are two typical 3D printer troubles that normally share the exact same source.What should I examine before 3D printing?

You'll additionally discover that when PLA spoils, it obtains fragile as well as conveniently breaks off.

Social Links