November 22, 2023

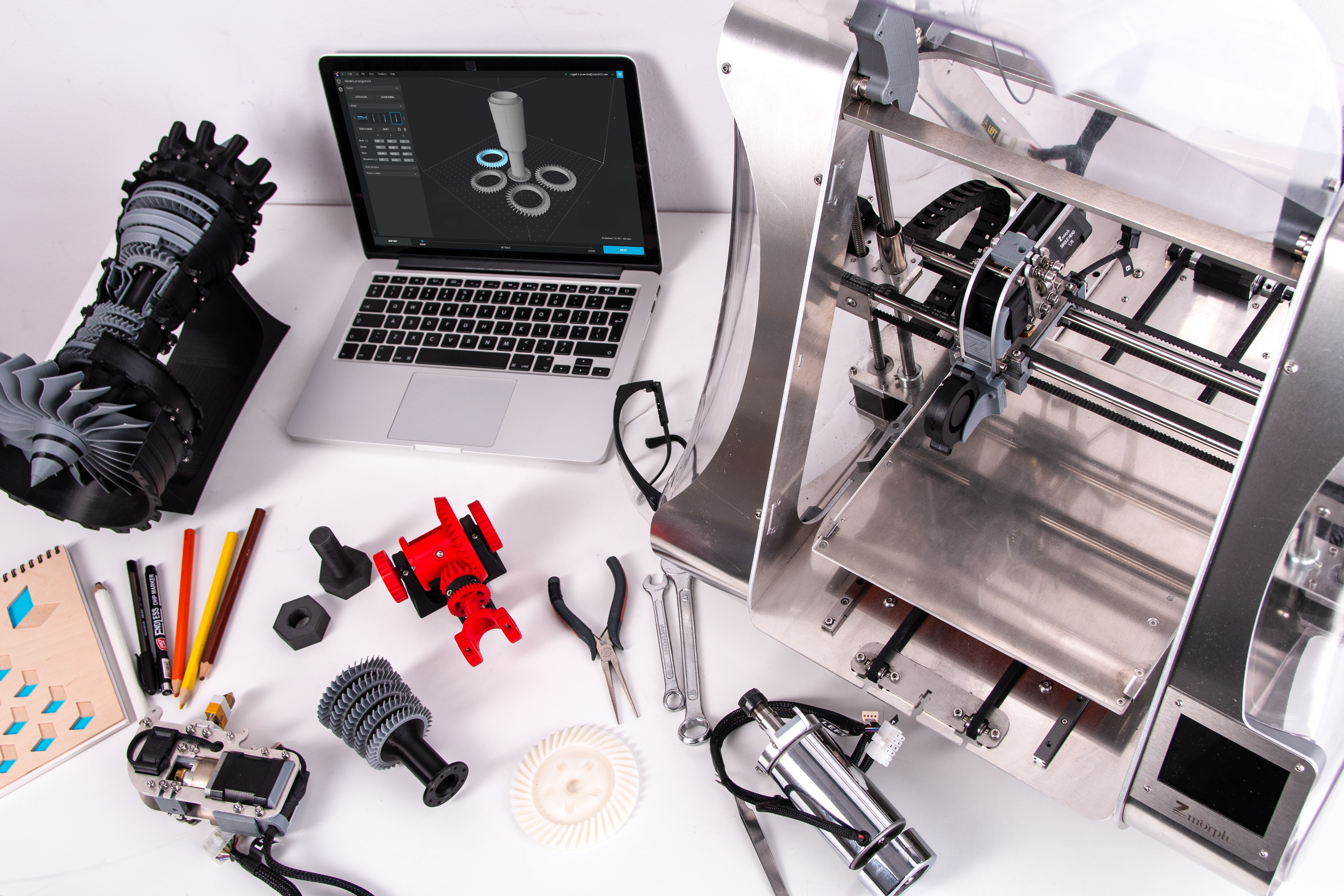

3d Printing Trends: 6 Major Advancements

Current Advancements In 3d Printing Of Biomaterials Journal Of Biological Engineering Complete Message To see where services are executing 3D printing in their methods today and in the future, download our sector report of 700 professionals. 3D printing likewise reduces labor by combining numerous component assemblies right into one single unit. Probably one of the most advanced advantage 3D printing uses is its integral style liberty. You finalize your layout with your project leader, publish your 3D CAD data to Stratasys Direct Production as well as select PolyJet prototyping.- A superb case instance of the style flexibility of 3D printing comes straight from NASA.

- Printed Castings -- Enhanced housing allows E-Motorcycle Batteries live longer By utilizing ingenious modern technologies such as 3D printing, the model can quickly go into series manufacturing.

- Scaffolds are developed by loading a 3D printed mold with porogen and polymer liquified in solvent by indirect 3DP.

- HA bits were coated with a water-soluble PVA using spray-drying or physical mixing.

- This is amongst the most innovative kinds of 3D printing with a great deal of potential in lots of premium applications.

-- Powder Bed Fusion

A development that will certainly not just completely transform the car of tomorrow, yet additionally the means it is constructed. As a leader of additive manufacturing, voxeljet offers 3D solutions to dramatically lower adaptability and response time in production. For wise production that can adapt to customer requirements in the fastest possible time.What is the development of 3D printing?

Improvements in 3D printing have made it less complicated for designers and also designers to tailor projects, create physical prototypes at various ranges, as well as generate structures https://sjc1.vultrobjects.com/large-format-printing-services/Fleet-Branding/real-world-examples/3d-print-quicker-12-tips-to-maximize-for-much-better.html that can't be made with even more standard manufacturing methods.

Plastic

As the area of 3D printing developments, a variety of post-processing techniques have arised to accommodate the varied requirements of various markets as well as applications. Vapor smoothing is a post-processing technique made use of primarily for 3D published parts made from polycarbonate materials such as ABS and ASA. The procedure entails exposing the published part to the vapor of a solvent, which liquifies the external layer of the material, successfully smoothing the surface and also eliminating layer lines. This method results in a glossy, expert finish, while likewise enhancing the component's mechanical residential or commercial properties, such as strength as well as watertightness. Seepage is an additional post-processing technique utilized to enhance the mechanical residential properties as well as surface area coating of SLS published parts. By fertilizing the get rid of a low-viscosity product, such as epoxy or cyanoacrylate, the part's porosity can be minimized, resulting in increased strength, rigidity, and also a smoother surface finish.Portolan Capital Management's Acquisition of Markforged Holding ... - Best Stocks

Portolan Capital Management's Acquisition of Markforged Holding ....

Posted: Sat, 10 Jun 2023 23:19:39 GMT [source]

Social Links