November 22, 2023

44 Usual 3d Print Issues Fixing Problems 2023

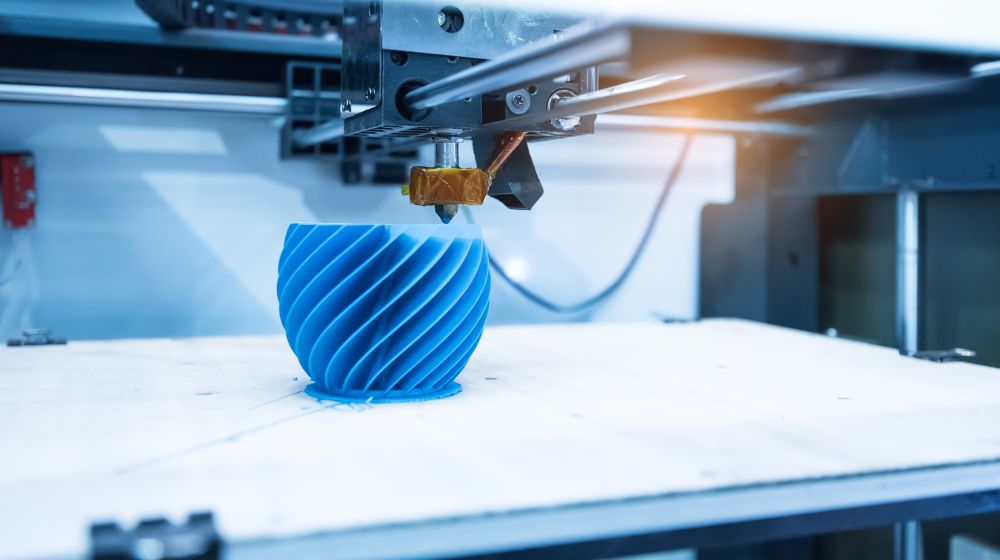

3d Printing Troubleshooting Guide Attempt switching to a smaller sized nozzle and see if you improve results. Sometimes, your nozzle might be harmed from long-term use, and the opening might be larger than it should. Over extrusion is the reverse of under extrusion, where you are squeezing out excessive filament compared to what your 3D printer is attempting to extrude. This variation is normally easier to take care of since it doesn't involve obstructions. I constantly advise people create temperature level towers for each and every brand-new filament to identify the optimal temperature for top quality. Check out the video listed below by Slice Publish Roleplay to find out exactly how to produce a temperature tower in Cura. First thing to try is to get rid of the filament in the common way. One individual stated they transform to SuperSlicer and it repaired this issue, while one more said PrusaSlicer helped them. You can download these slicers absolutely free as well as attempt them bent on see if it helps you. It could be a sign that your velocity and also jerk setups are too expensive. The higher the mass of your extruder, the a lot more vulnerable it is to these artefacts when publishing at higher rates. A lot more generally vibrations and 3D printing ringing are caused by mechanical issues but there are a number of settings that might also create this concern.Little Components & Features Not Printing

Specify your printer, mainboard, stepper motorists, firmware, modifications, slicer, and so on. Tuning the present provided to the stepper electric motors varies considerably relying on these variables. Publishing slower permits the warm building up in the printed object to dissipate before the following pass of the nozzle over the exact same area of the print. Do the standard extrusion calibration of extruder steps/mm and extrusion multiplier. Assistance frameworks are generally not printed strong, yet instead, like infill, utilize a percent, commonly called assistance thickness. Boost this density to improve the surface top quality of the part printed over the support.3D Printing News Briefs, March 2, 2023: Micro 3D Printer & In-Situ Inspection & More - 3DPrint.com

3D Printing News Briefs, March 2, 2023: Micro 3D Printer & In-Situ Inspection & More.

Posted: Thu, 02 Mar 2023 08:00:00 GMT [source]

Charred Things Dripping On Your Print

After that include a bit of lubrication and run some control software that will certainly relocate the head. In this manner you can guarantee that every little thing is equally covered and there are not any 'bumps' in the means everything relocations. Use a lint-free towel to remove the excess oil if you've included too much.- So, give it the interest it deserves and also print infill like an important component of the design.

- There's also a chance of clogging due to product accumulation.

- Nonetheless, it can be utilized with an unheated unit and even on an open printer with a basic draught guard (it's the drafts that matter most!).

- Trouble Common Cause Correction Online Forum Link If you are not certain concerning having actually properly calibrated your printer, confirm that it is adjusted first as that is the initial step.

- However when it comes to publishing a great detail, the final product has a great deal of misprints.

- Turn the printer on - Some mainboards will revive entirely from a 5V USB wire, where as others need the main power switch switched on.

What are the common 3D printing troubleshooting problems?

- Not Extruding at Begin of Print. Printer does not squeeze out plastic at the start of the print.Not Adhering to the Bed.Under-Extrusion. Over-Extrusion.

- Voids in Top Layers.Stringing or Oozing.Overheating.Layer Shifting. Size.

- One attribute to think about when

- creating your thing is it's scale.The resolution.

- Throughout additive production, the resolution describes the thickness of each layer of material being'applied.Wall thickness.The orientation.The selection of

- material.Design equilibrium. When a PLA filament absorbs wetness, it inflates, raising the danger of extruder jams. Wetness likewise triggers PLA to produce prints with bubbles and voids on the surface, for that reason ruining your prints

- .

Social Links