November 22, 2023

3d Printer Repairing Guide

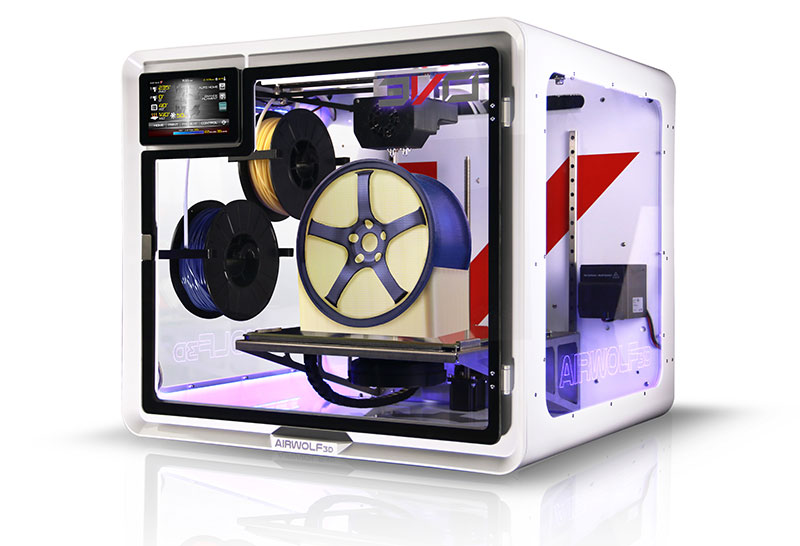

Print High Quality Overview The size of the filament is an additional issue and also this factor can differ from producer to maker and batch to set. In addition, if the idler tensioner on the extruder is also tight, the pressure might create also top quality filament to break. Nevertheless, frequently the most usual is a little remaining item of filament from a previous spool.3D Printing Financials: Velo3D Makes Killer Q4 Earnings - 3DPrint.com

3D Printing Financials: Velo3D Makes Killer Q4 Earnings.

Posted: Wed, 08 Mar 2023 08:00:00 GMT [source]

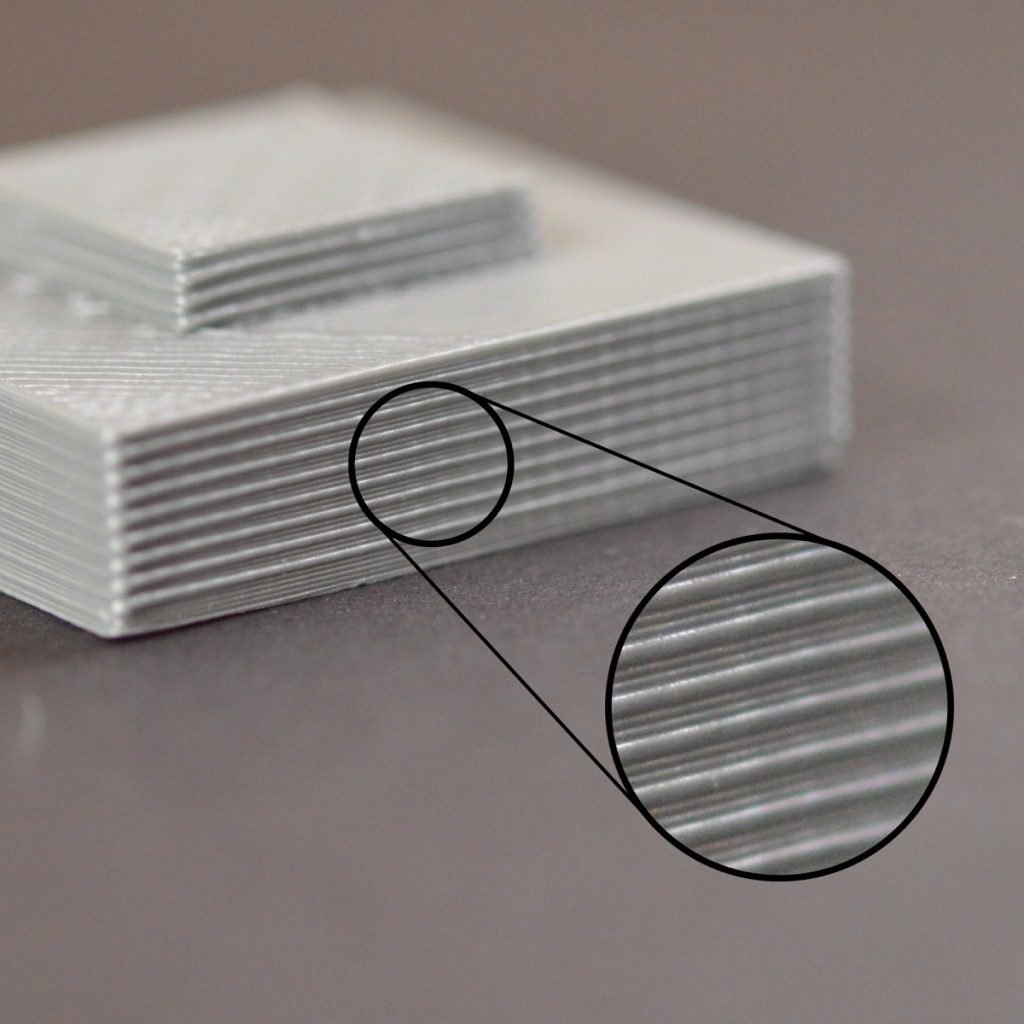

Platform Not Level

Similar to under extrusion, you can do https://objects-us-east-1.dream.io/custom-printing/Offset-Printing/history-of-printing-press/new-3d-printing-process-is-much-faster-and-also-much-more-exact-than.html this in 5-10 ° C increments until your extrusion is back to regular. The procedure is to squeeze out filament and determine just how much was extruded, then inputting a new worth for your extruder actions per mm in your 3D printer's firmware. One of the possible fixes for under extrusion is to calibrate your extruder steps (e-steps). Simply put, extruder actions are just how your 3D printer identifies just how much the extruder relocates filament via the nozzle. Under extrusion is common issue that individuals complete 3D printing. One more uncommon cause is the nozzle temperature level, however that will hold true just if you utilize cheap, incompatible or out-of-date filaments. The latter will certainly once more cause a path of material as a result of the boosted recurring warm of the nozzle. Before printing, make certain to get rid of any kind of excess product or cloggings left in the nozzle, or else it won't be able to properly squeeze out the product. Also the least obstruction will cause noticeable misprints and also lead to a crude-looking product. Complying with those remedy, it's extremely desirable to fix non-manifold geometry problems of the design before uploading it right into the slicer software.Layer Moving

If the slipping has actually just begun to happen, the shavings and noise are normally obvious. You can slightly use the stress to the filament, assisting it to move. If the freshly loaded filament breaks also, attempt to loosen the idler tensioner as much as feasible. Then tighten it after launching printing until it does not slide anymore.What are the usual 3D printing troubleshooting problems?

- Not Extruding at Start of Publish. Printer does not extrude plastic at the beginning of the print.Not Sticking to the Bed.Under-Extrusion. Over-Extrusion.

- Spaces in Top Layers.Stringing or Oozing.Overheating.Layer Shifting. Dimension.

- One feature to take into consideration when

- developing your item is it's scale.The resolution.

- Throughout additive production, the resolution refers to the thickness of each layer of material being'applied.Wall thickness.The orientation.The option of

- material.Design balance. When a PLA filament absorbs moisture, it inflates, raising the threat of extruder jams. Moisture additionally triggers PLA to create prints with bubbles and also spaces on the surface, therefore destroying your prints

- .

- The latter will once again cause a path of material as a result of the raised recurring heat of the nozzle.

- Some stepper motor chauffeurs don't play well with linear/pressure advancement.

- As well as if there is, the print might end up with an absence of sticking or with the missing layers.

- The temperature of the bed also plays a vital duty in this.

- Another bright concept would be to look for such errors by hand in order to avoid any kind of misprints.

- Occasionally problems with 3D printing can be fixed by starting to 3D print infill before your main covering is printed, or by servicing reduced print speeds.

Social Links